Parts feeder / List of 21 manufacturers

What is a Parts feeder?

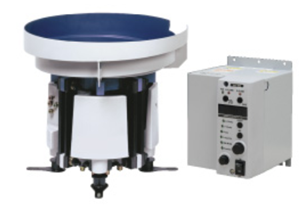

A parts feeder is an automation device used in the manufacturing industry to orient and supply parts or components in a specific direction. It is primarily used in production lines to supply parts one by one, playing a crucial role in enhancing work efficiency. If parts are supplied randomly, manual sorting is required, which reduces productivity. By using a parts feeder, parts are aligned correctly and passed smoothly to the next process by machinery or operators.

There are various types of parts feeders, such as vibrating feeders, rotary feeders, and air feeders. These feeders are designed to accommodate parts of different shapes and sizes. In addition, parts feeders are often referred to as linear feeders or vibration feeders. In automated production lines, they are essential for improving the reliability of parts supply and boosting productivity.

Application of Parts feeder

✅ Automotive Part Supply

In automotive manufacturing lines, parts feeders are used to automatically supply engine parts and small components, reducing manual labor and increasing production speed.

✅ Electronics Assembly

In electronics assembly lines, parts feeders supply small components like resistors and connectors. This reduces the manual handling and allows for efficient, precise assembly work.

✅ Medical Equipment Manufacturing

In the production of medical devices, parts feeders supply small precision parts or screws accurately. This is especially useful when high dimensional accuracy is required.

✅ Food Manufacturing Industry

In food production lines, parts feeders are used to supply containers and packaging materials. This automates the placement of parts and boosts production efficiency.

➡️ We are looking for companies in Thailand that handle and provide demo units of Parts feeder.

➡️ MAB THAILAND is seeking distributors, sales partners, and manufacturers for Parts feeder.

➡️ Please feel free to contact us!

Hightlights of Parts feeder

Manufacture list of Parts feeder

※Includes information on some trading companies

-

-

-

Our company specializes in providing products (software, automatic sorting machines, automatic sorting services) tailored to contribute to the quality assurance of mass-produced parts manufacturers. We work with our customers to develop methods for controlling the occurrence of defective products in the manufacturing process and ensuring compliance with manufacturing rules. We also consider measures such as conducting high-speed automatic sorting of all products before shipment to prevent the delivery of defective products. We build systems that allow for easy analysis of manufacturing data within the process, and we explore ways to achieve fundamental improvements in quality. We propose products, services, and facilities to solve these challenges and support our customers' businesses, helping you achieve zero parts per million (ZERO PPM) defect rates.

Published Media

✅ Fact-Link ✅ Samurai Asia