Jig and tool design / List of 17 manufacturers

What is a Jig and tool design?

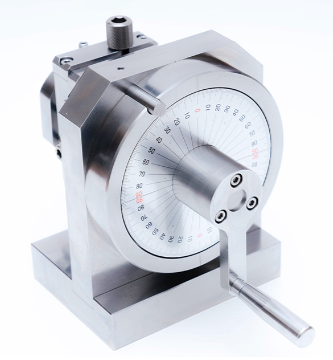

Jig and tool design refers to the process of creating specialized tools and fixtures used to ensure precise and efficient manufacturing operations. Jigs hold and position the workpiece securely, while tools are used for cutting, grinding, or forming during the production process. In designing jigs and tools, engineers consider factors such as the shape and material of the workpiece, required accuracy, and production efficiency to develop the most effective solutions. Jigs prevent movement or deformation of the workpiece during machining, ensuring precision. Tools, on the other hand, are responsible for performing the machining itself, such as cutting or grinding. Proper jig and tool design directly contribute to reducing manufacturing costs, improving productivity, and ensuring consistent quality.

With the rise of automation and robotics in manufacturing, jig and tool design plays an increasingly critical role in modern production environments.

Application of Jig and tool design

✅ Assembly Jigs for Automotive Parts

In automotive manufacturing, high-precision jigs are used for assembling complex parts like engines and body panels. These jigs allow workers to securely hold components in place, minimizing errors and enabling rapid assembly. By using jigs, consistent quality can be maintained, even with different operators.

✅ Precision Machining Jigs in Semiconductor Production

Semiconductor manufacturing requires precision at the 1/1000 millimeter level. Jigs for securing wafers and tools for grinding are specifically designed to achieve this accuracy. This helps reduce defects while allowing for mass production of intricate components.

✅ Jigs for Aircraft Component Machining

Aircraft manufacturing demands lightweight, high-strength components. Jigs used in conjunction with CNC machines fix parts in precise positions, ensuring high machining accuracy. Specialized jigs are essential, especially for processing engine components and airframe structures.

✅ Assembly Jigs for Medical Devices

The production of medical devices requires precise assembly and high quality. For instance, jigs are used in the manufacturing of artificial joints and dental implants to accurately position and assemble parts down to the millimeter level. This ensures safety and quality while enabling mass production.

These examples illustrate how jig and tool design significantly contributes to improving product quality, enhancing production efficiency, and reducing costs.

Hightlights of Jig and tool design

Manufacture list of Jig and tool design

※Includes information on some trading companies

-

-

-

KUROITSU (THAILAND) CO., LTD. Comprehensive Automation Solutions! The FA & Robotics System Experts!!

KUROITSU (THAILAND) CO., LTD. was established in Thailand in 2008 as a wholly-owned subsidiary of Kreuz Co., Ltd., the pioneer in deburring automation. Since our founding, we have been committed to the development and implementation of automation technologies, with a focus on deburring. Today, we provide a wide range of FA and robotic systems across various industries.

We have delivered over 300 systems within Thailand, contributing to improved productivity and labor-saving solutions at manufacturing sites.

Our strength lies in our ability to handle the entire process in-house—from concept design and manufacturing to installation and after-sales service.

Our experienced engineers accurately analyze customer challenges and build custom-made robotic systems and special-purpose machines tailored to specific needs. We provide optimal solutions for issues such as labor shortages, cost reduction, and productivity improvement.

If you are considering implementing automation or labor-saving production lines using robots or custom machinery in Thailand, please contact KUROITSU (THAILAND) CO., LTD.

With our technical expertise and proven track record, we are here to support your manufacturing site.

Group company

✅ KREUZ.CO.LTD. (Japan)

✅ KT CO., LTD. (Japan)

✅ KREUZ KOREA CO., LTD. (Korea)

Partners

✅ TOVONN TECHNOLOGY CORPORATION (Taiwan)

✅ HYOJUN PRECISION COMPANY LTD. (Korea)

✅ SARL Techplus (France)

✅ August Mossner GmbH + Co. KG (Germany)

✅ AF Industries AB (Sweden)

-

-

-

SANKO SEIMITSU CO., LTD. is a team of engineers specialized in manufacturing semiconductor components, electrical parts for motorcycles and automobiles, and low-voltage components requiring 1/1000 mm precision. The company is highly regarded for its production of precision progressive press molds and metal components, trusted across industries such as semiconductors, automotive, and medical. In 2019, SANKO SEIMITSU established a joint venture in Indonesia, accelerating its business expansion into the Asian market.

The company also plans to expand its operations in the Thai market. By meeting local demands and providing high-precision technology and products, SANKO SEIMITSU aims to build further trust and a strong track record.